Resource Library

Market Info Sheets – Flexible Markets

SURPASS® HPs267-AB

SURPASS® HPs267-AB resin sets the new standard in moisture-barrier performance with longer shelf by protecting moisture sensitive layers and products in food packaging.

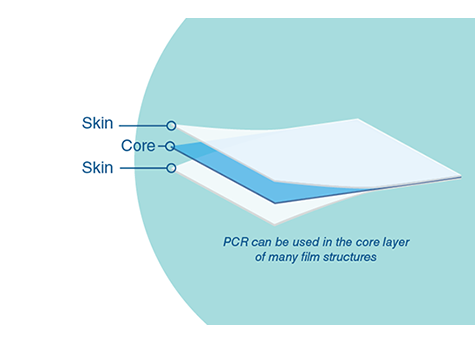

Post Consumer Resin in Flexible Packaging

Polyethylene offers a unique opportunity to move from multi-material to recyclable monomaterial films in a wide range of applications.

High-Density BOPE

Biaxially oriented polyethylene (BOPE) offers a recyclable replacement to biaxially oriented polypropylene (BOPP) and PET (BOPET) multi-material laminates or metalized structures.

Collation Shrink

The growing demand for shrink films is driving innovation throughout the polyethylene value chain. At NOVA Chemicals, we work with our customers to understand their needs and the needs of their customers.

NOVAPOL® PF-Y818 Series Resins

Achieve up to a 20% increase in blown film extrusion output relative to traditional 1MI butene LLDPE – without compromising physical properties – with the NOVAPOL PF-Y818 resin series.

Recyclable PE Barrier Film Designs

Look no further. NOVA Chemicals has developed a range of film structure designs with all the features you expect of high-performance flexible packaging – and the added benefit of recyclability.

SPsK919 Resin

In a new economy built around e-commerce and sustainability, packaging requirements are rapidly changing.

SPs116 Resin

SPs116 is part of new class of resins, developed with our Advanced SCLAIRTECH Technology, that enables operational simplicity and flexibility.

VPsK914 Resin

VPsK914 is part of a new class of sealant resins, developed with our Advanced SCLAIRTECH Technology, that enables an unbeatable combination of physical properties and processability.

SURPASS® FPs016-C LLDPE Resin

SURPASS FPs016-C linear low density polyethylene (LLDPE) resin is a versatile performer in a wide range of applications. It offers an ideal combination of toughness, high seal strength and improved optics (in blends).

SURPASS® HPs167-AB Resin

Achieve ultra-high moisture-barrier performance with SURPASS HPs167-AB resin.

SURPASS® HPs667-AB sHDPE Resin

Obtain superior barrier and stiffness performance vs. traditional HDPEs with SURPASS HPs667-AB ultra-high barrier sHDPE resin.

Ready-to-Recycle Portfolio

Answer the demands of a circular economy with NOVA Chemicals’ ready-to-recycle resins.

Market Info Sheets – Rigid Markets

NOVAPOL TRx0338 & TRx0535

Fast-Cycling 3- & 5-Melt Rotational Molding Resins – These resins can reduce cycle times by up to 30%, provide a processing window at least 15% broader than traditional hexene rotomolding resins, and improve low-temperature impact properties.

Caps & Closures

At NOVA Chemicals, our mission is to be the leader in innovation that enables our customers to deliver plastic products that make everyday life healthier, easier and safer.

NOVAPOL® HB-W646-UX Resin

Increase productivity and revenue with NOVAPOL HB-W646-UX resin, without the need to invest in new equipment.

SURPASS® CCs154 Resin

For closures that must meet the strictest processability and performance requirements CCs154 delivers superior ESCR and organoleptics for next-generation beverage closures.

SURPASS® RMs245-U/UG Resin

Get an industry-leading combination of stiffness, toughness and ESCR in a wide range of applications with SURPASS RMs245-U/ UG resin.

SURPASS® Resins For Rotational Molding

NOVA Chemicals has developed novel, world class catalyst & reaction technologies to create innovative, industry leading resins designed specifically for the needs of rotational molders.

Quality Rotomolding Resins

Our portfolio of polyethylene rotational molding resins create value and offer a competitive advantage. By improving process and material efficiencies, our resins enable the development of solutions that are more innovative, cost-effective and better performing.

Other Materials

Introducing NOVA Chemicals’ First Mechanical Recycling Facility

NOVA Chemicals’ Circular Solutions business has invested in a Connersville, IN, facility to increase the supply of high-quality, recycled polyethylene resins.

Survey Insights White Paper: Inside the Mind of the Consumer

Shoppers increasingly value plastic packaging benefits, seek sustainable solutions

White Paper: Inflection Point

Consumer research reveals opportunity to focus on impactful sustainability initiatives

Anita’s Organic Mill/Emmerson Packaging Case Study

What’s the Recipe for Sustainable Packaging?

BONFIRE Brochure Booklet

The brochure for our BONFIRE Film Modeling Platform

Centre for Performance Applications Fact Sheet

Fact sheet for our Centre for Performance Applications facility.

DuraCast Case Study

Collaborating for Success – a NOVA Chemicals case study with Florida’s largest rotomolder.

Tech Bulletins

Blending Tie Concentrates with LLDPE Resins

High barrier resins such as ethylene vinyl alcohol (EVOH) and nylon require an intermediate adhesive or tie layer to bond to polyolefin layers and maintain package integrity.

Die Lip Building: Causes and Remedies

Die lip buildup (DLBU) or die drool is the gradual accumulation of material on the die lips or at the exit of extrusion dies. DLBU can be a chronic problem in high-output cast film or extrusion coating operations and is generally more likely to occur when extruding polymer blends that are highly filled or pigmented.

Preventing Gas Fading in Polyethylene

Gas fading is a yellow or pink discoloration that happens when atmospheric pollutants like nitrogen oxide gases react with phenolic-type antioxidants. It’s a common issue with polyethylene films.